Basic Information:

| Place of Origin: | CHINA |

| Brand Name: | Andea Electronics |

| Model Number: | AR2301M |

| Minimum Order Quantity: | 1 Piece |

| Packaging Details: | Standard Export Carton, Foam and Protective Film |

| Delivery Time: | 7~15 work days |

| Payment Terms: | T/T, Western Union, Paypal |

| Supply Ability: | 500~1000 Sets Per Month |

Product Features:

Support Modbus communication mode,Convenience to interface with various PLCs.

With high sensitive read-write performance.

Integrated design,easy to installation and deployment.

With IP67 protection grade can adapt to harsh environments.

Built-in-one design,have strong anti-interference ability to EMC.

| Reading Range | 0~140mm | Operating Frequency | 13.56 MHz |

| Support Standard | ISO 15693 | Communication Rate | 9600~115200 Bit/s |

| Communication Mode | RS485(Modbus RTU) | Current | <0.30A@24V DC |

| Dimension | 100*100*35mm | Waterproof/dustproof | IP67 |

| Weight | 160g | Interface | M12A(4pin M) + M12A(5pin M) |

Specification of Integrated rfid reader:

|

Specification |

|

|

Support Standard |

ISO 15693 |

|

Operating Frequency |

13.56MHz |

|

Reading Range |

0-180mm |

|

Communication mode |

RS485(Modbus RTU) |

|

Communication rate |

9600~115200 bit/s |

|

Power Supply |

24V DC(9-30V) |

|

Current |

<0.03A@24V DC |

|

Physical parameters |

|

|

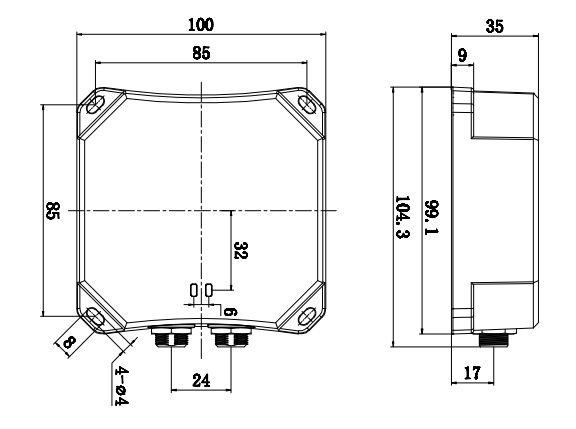

Dimension |

100*100*35mm |

|

Weight |

160g |

|

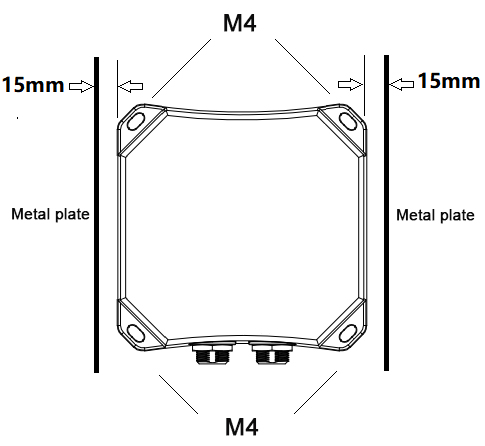

Fixed type |

4*M4 screw |

|

Housing Material |

ABS and Metal plate |

|

Color |

Black |

|

Indicator light |

LED*2 |

|

Interface |

M12A(4pin M) + M12A(5pin M) |

|

Application environment |

|

|

Working Temperature |

-40℃~+85℃ |

|

Humidity |

5%~95%RH |

|

Waterproof/dustproof |

IP67 |

Product Application:

Power Battery Assembly

Install the reader at the RFID collection point, and the on-line station collection point reads the RFID tag in the material box to obtain the information of slots in the material box (each slot is equipped with a cell with different voltage), The voltage value/grade of the test cell is written into the material box RFID tag at the test station of the voltage cell. When the cell is classified, read the RFID tag information of the material box and connect the robot in real time to automaticaly put the cell into the corresponding cell transport track. After the robot takes down the cell with different gear from the transport track and puts them into the same material box it will write the cell gear information into the RFID tag of the material box. Through the operation of each station on the RFID tag, a series of processes such as cell division, transportation, encapsulation, and assembly are completed in the process of cell assembly.

Factory Automation

This product has always been a key player in the field of discrete manufacturing with its strong portfolio comprising sensors, connection and fieldbus technologies, RFID and control solutions. Our comprehensive solutions help our customers to improve efficiency, increase availability and minimize errors.

Efficient RFID identification solutions for process optimization, help improve tool recognition and complete traceability of production and logistics processes.

Dimension Drawing(mm):

Installation Instruction:

This reader use four M4 screws to fixing. According to the installation environment of the site,we can support bracket to install.If there has Metal plate beside the product,please make sure that the distance between reader and Metal plate has more than 15mm,or it will influence the performance of reading and writing.

When there are more than two readers to be installed, the distance between the readers needs to be greater than 850mm.

![]() Company:Andea Electronics

Company:Andea Electronics

![]() Address:Room 401, Building H, Jingye 3rd Street, Yushu Industrial Park, Economic And Technological Development Zone, Guangzhou 510663

Address:Room 401, Building H, Jingye 3rd Street, Yushu Industrial Park, Economic And Technological Development Zone, Guangzhou 510663

![]() Telephone:86-20-32039550

Telephone:86-20-32039550

![]() Email:marketing@gzandea.com

Email:marketing@gzandea.com