| Place of Origin: | CHINA |

| Brand Name: | Andea Electronics |

| Model Number: | AI21P-RS4-D8 |

| Minimum Order Quantity: | 1 Piece |

| Packaging Details: | Standard Export Carton, Foam and Protective Film |

| Delivery Time: | 3~5 work days |

| Payment Terms: | T/T, Western Union, Paypal |

| Supply Ability: | 500~1000 Sets Per Month |

Protocol Conversion: The Modbus gateway acts as a bridge between the Modbus protocol used by the PLC and other protocols such as Ethernet/IP, TCP/IP, Profinet, or others. It provides the capability to translate data between these protocols, ensuring compatibility and seamless communication.

Multiple Protocol Support: A Modbus gateway may support multiple protocols, allowing it to communicate with a wide range of devices or applications that use different protocols. This versatility enables integration with diverse systems within the network.

Data Mapping and Configuration: The Modbus gateway typically provides configuration options to map data between the PLC and the target devices or applications. It allows defining the data points to be collected, specifying addresses, registers, or tags for data retri or writing.

Data Filtering and Filtering: The gateway may offer filtering and aggregation capabilities to optimize data collection. It allows users to select specific data points or ranges of data to be collected, minimizing unnecessary network traffic and improving efficiency.

Diagnostic and Monitoring Tools: A Modbus gateway often includes diagnostic and monitoring tools to assist in troubleshooting and analyzing communication issues. These tools provide visibility into the data flow, monitoring connection status, and detecting any errors or anomalies.

Security Features: To ensure secure communication, a Modbus gateway may offer encryption and authentication mechanisms. This helps protect the data exchanged between the PLC and other devices or applications from unauthorized access or tampering.

Scalability and Flexibility: The Modbus gateway can scalable and flexible to accommodate the needs of the network. It supports a sufficient number of devices or applications and allow for easy expansion as the network grows or requirements change.

| Physical Parameter | Dimensions | 205*60*35.4mm |

| Material | Aluminum alloy | |

| Power Supply | Voltage | 24VDC |

| Current | 8A | |

| Interface | 5 Pin M12 (1 A and 1 D) L | |

| Power Interface Description |

2 Power Interfaces

(V1:for RFID V2:for Sensors, Actuators)

|

|

| LED |

2 power indicator lights,

2 bus communication indicator lights,

4 card reading status indicator lights,

4 RS485-MODBUS RTU running indicator lights,

4 RS485-MODBUS RTU fault indicator lights,

8 GPIO status indicator lights

|

|

| Communication | Protocol | Modbus TCP |

| Communication Rate | 10Mbps/100Mbps | |

| Connector | 4 Pin M12 *2 | |

| DI/DO Points | 8 Channels | |

| DI/DO Interface | 5 Pin M12 A | |

| RFID | RFID Quantity |

4 Independent Channels

(Each Channel can connect with more than 32 readers)

|

| RFID Interface | 5 Pin M12 A | |

| Environment Adaptability | Working Temperature | -40℃~+85°C |

| Storage Temperature | -40℃~+85 °C | |

| Protection Level | IP67 |

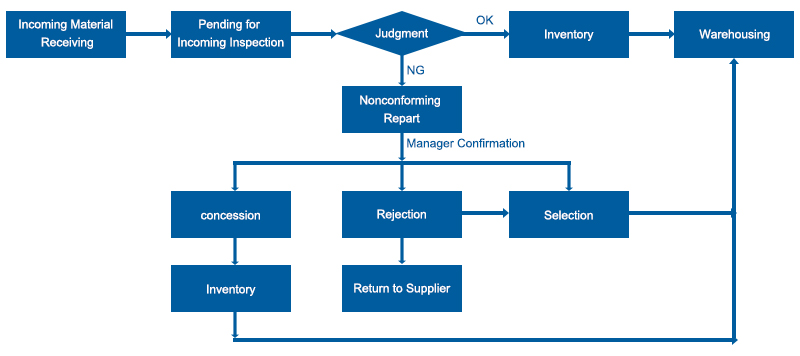

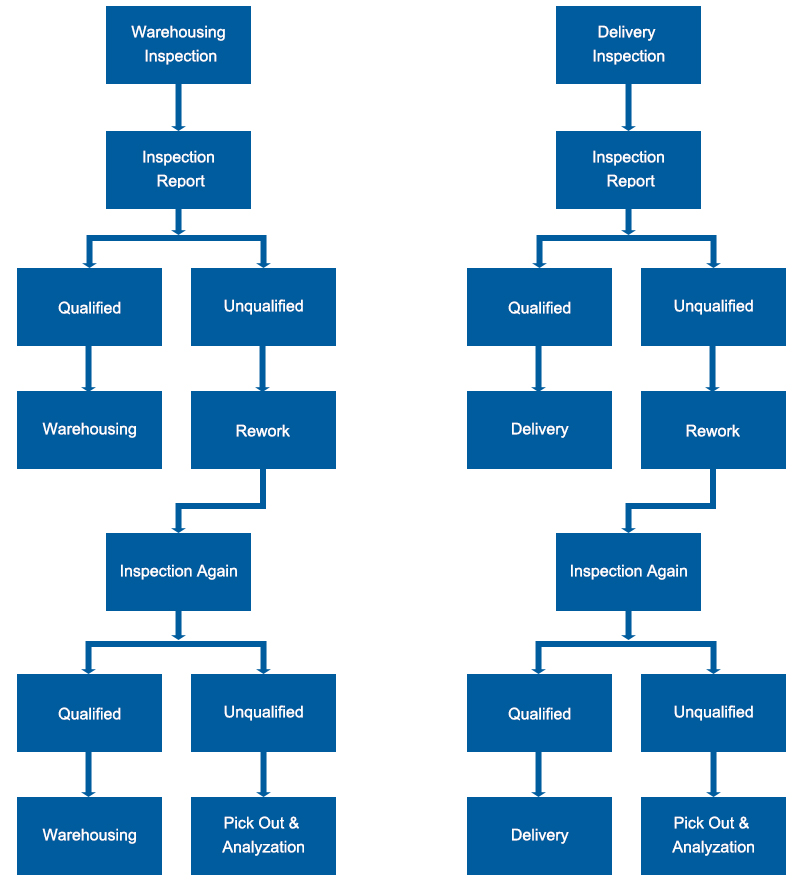

As a professional and practised manufacturing company, we have buit up a series of workable and effective quality control system. Below are two major quality control inspection:

1.Purpose:

Checking all incoming material including sub-contractor provide products to ensure the quality meet requirement and nonconformity is found in time so as to prevent released nonconforming incoming material.

2.Scope:

Incoming materials (Expect some material for mold making and ship-to-stock material), including customer- supplied material and sub-contactor supplied products.

3.Definition: N/A

3.1 RMT: RMT is the short form of Reiving Move Ticket.

3.2 MRB: MRB Store means the rejected area assigned by store.

4.Responsibility:

4.1 IQC is responsible for the inspection and test of all in-coming material and parts.

4.2 Purchasing is responsible for informing non-conforming material to vendors / sub-contractors.

5. IQC Flow Chart

1. Free SDK, communicaiton protocols and R-Tool (testing & configuration software) provided.

2. Professional hardware and software engineers to give online or offline support.

As we have rich experien of many RFID projects after ten years development , especially in RFID library management, RFID personnel management (time and attendan management), RFID jewelry management, RFID casino management, RFID fast food shop management, production line automation, etc., we are able to give recommendation of the most suitable hardware solution in professional advis.

As the industry leader in the China RFID industry, we have to prove that we are committed to the confiden of our products. Free warranty is three year for all of our RFID reader and antenna excluding human factor damage.

![]() Company:Andea Electronics

Company:Andea Electronics

![]() Address:Room 1101, 1102, Building C2, No. 29, Bishan Street, Huangpu District, Guangzhou, Guangdong, China.

Address:Room 1101, 1102, Building C2, No. 29, Bishan Street, Huangpu District, Guangzhou, Guangdong, China.

![]() Email:marketing@gzandea.com

Email:marketing@gzandea.com