Basic Information:

| Place of Origin: | CHINA |

| Brand Name: | Andea Electronics |

| Model Number: | ARU2301M |

| Minimum Order Quantity: | 1 Piece |

| Packaging Details: | Standard Export Carton, Foam and Protective Film |

| Delivery Time: | 7~15 work days |

| Payment Terms: | T/T, Western Union, Paypal |

| Supply Ability: | 500~1000 Sets Per Month |

RFID UHF Reader Features:

Support Standard:ISO18000-6C,EPC C1G2;

Communication mode:Modbus RS485;

Fixed type:4*M4 screw;

Waterproof/ dustproof:IP67;

Communication Interface:M12A(4pin M) + M12A(5pin M);

| Operating Frequency: | 860~960MHz | Support Standard: | ISO18000-6C、EPC C1G2 |

| Reading Range: | 0~3m | Communication Rate: | 9600~115200 Bit/s |

| Communication Mode: | Modbus RS485 | Interface: | M12A(4pin M) + M12A(5pin M) |

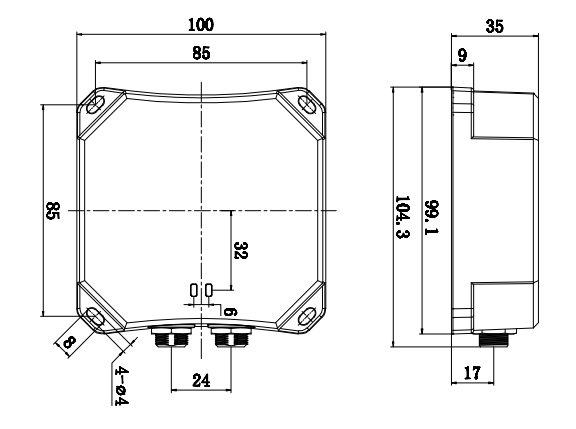

| Dimension: | 100*100*35mm | Waterproof/dustproof: | Support(IP67) |

Specification of RFID UHF Reader:

|

Specification |

|

|

Support Standard |

ISO18000-6C,EPC C1G2 |

|

Operating Frequency |

860~960MHz |

|

Reading Range |

0-3m |

|

Communication mode |

Modbus RS485 |

|

Communication rate |

9600~115200 bit/s |

|

Power Supply |

24V DC(10-30V) |

|

Current |

<0.38A@24V DC |

|

Physical parameters |

|

|

Dimension |

100*100*35mm |

|

Weight |

639g |

|

Fixed type |

4*M4 screw |

|

Housing Material |

ABS and Metal plate |

|

Color |

Black |

|

Indicator light |

LED*2 |

|

Interface |

M12A(4pin M) + M12A(5pin M) |

|

Application environment |

|

|

Working Temperature |

-30℃~+60℃ |

|

Humidity |

5%~95%RH |

|

Waterproof/dustproof |

IP67 |

RFID UHF Reader Application:

Factory Automation

Distributed Production Line of Automotive Seats

installed RF tags on the bottom of seat pallets. As each seat progresses down the assembly line, the pallet passes over an antenna at each workstation. Operators reference a touchscreen PLC that indicates seat type as well as needed alterations.

If a seat requires work, the operating system won't let the seat continue down the line until the operator has made and verified all necessary adjustments. The antenna then writes to the tag, updating it with whatever modifications have been made to the seat.

The process continues until the seat reaches the final workstation where its build instructions are verified with the actual assembly record. If they match up, the seats are transferred to the shipping area and are sequenced for delivery to the automaker's assembly line.

RFID system allows operators to assemble many different types of seats on the same production line.

Optimize processes in Production and Logistics

Industrial RFID readers are especially common in the field of intralogistics and so-called “gate applications”. The HF technology is an important driver of digital production processes and the HF RFID readers have been used successfully in production processes for many years. Among other things, you can also use the read/write heads for fast and reliable tracking of material in intralogistics, tracking of individual products, tracking of transport carriers through the production process.

Power Battery Assembly

Install the reader at the RFID collection point, and the on-line station collection point reads the RFID tag in the material box to obtain the information of slots in the material box (each slot is equipped with a cell with different voltage), The voltage value/grade of the test cell is written into the material box RFID tag at the test station of the voltage cell. When the cell is classified, read the RFID tag information of the material box and connect the robot in real time to automaticaly put the cell into the corresponding cell transport track. After the robot takes down the cell with different gear from the transport track and puts them into the same material box it will write the cell gear information into the RFID tag of the material box. Through the operation of each station on the RFID tag, a series of processes such as cell division, transportation, encapsulation, and assembly are completed in the process of cell assembly.

Dimension Drawing(mm):

Installation Instruction:

This reader use four M4 screws to fixing. According to the installation environment of the site,we can support bracket to install.If there has Metal plate beside the product,please make sure that the distance between reader and Metal plate has more than 50cm,or it will influence the performance of reading and writing.

When there are more than two readers to be installed, the distance between the readers needs to be greater than 10m.

![]() Company:Andea Electronics

Company:Andea Electronics

![]() Address:Room 1101, 1102, Building C2, No. 29, Bishan Street, Huangpu District, Guangzhou, Guangdong, China.

Address:Room 1101, 1102, Building C2, No. 29, Bishan Street, Huangpu District, Guangzhou, Guangdong, China.

![]() Email:marketing@gzandea.com

Email:marketing@gzandea.com